BD76 brushable anti skid corrosion resistant epoxy coatings

BD76 brush coating type anti skid corrosion resistant epoxy resin coatings

Product usage:

This product is a two-component high polymer anti skid coating cured at room temperature. It is mainly used for anti skid coating paving of metal stairs, corridor, slope and other places in industrial and mining enterprises.

Performance features:

1. High strength, good toughness, very high bonding strength with metal, cement and other materials;

2. Moderate viscosity, roller coating construction, simple and fast operation, no high technical requirements for construction personnel.

Performance index:

|

Performance parameter table |

|||||||||

|

Color |

Physical state |

Construction method |

Maximum size of non-slip particle |

Density |

Compressive strength |

Hardness |

Operational time limit |

The required curing time before putting into using |

Working temperature range |

|

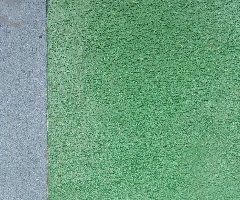

Green |

Dilute paste |

Roller coating |

60 mesh |

1.7±0.1 |

>9 |

>80 |

≥30min |

>12h |

-60¡æ¡«80¡æ |

Note: the curing conditions of samples (sample blocks) used in all the test data in this note are: 25¡æ 24h + 80¡æ 4h.

How to use:

1. Surface treatment: clear up the pending-repair parts,expose the fresh substrate,do the roughing treatment for the fresh substrate,the treated surface should be a dry, rough, clean fresh material surface.

2. Peripheral protection: Use adhesive tape to stick around the parts to be constructed to protect the parts that need not be constructed from pollution.

3. Preparation: accurately weigh out the right amount of A and B components according to the proportion required by product labeling,and stir them thoroughly to mix them evenly.The prepared material should be

used up within the specified operating time (that is, before the material starts to become sticky, and the material after becoming sticky and hard can’t be used again)

4. Coating: Make the mixed prepared material be coating on pending repair parts evenly with a rolling brush.When rolling, press down hard and roll in the same direction.

5. Remove perimeter protection: After finishing the construction of an area,remove the perimeter protection tape immediately, taking care not to damage the neat edges of the coating.

6. Curing: It can be put into using under the light load after curing 12 hours at room temperature 25¡æ,when the construction ambient temperature is too low,heating or prolonging curing time should be used to complete the curing.

Special version:

1. The product parameter is obtained for laboratory testing,only for reference,due to the actual working condition is more complex,suggest the users to do the pretest according to actual working condition.

2. The above method of use is only a general guiding scheme, please determine the appropriate construction scheme according to the actual conditions on the site before the formal construction

3. When the environment temperature is below 25¡æ,the required curing time will prolong,should take proper heating measure to expedite the curing speed

4. When the environment temperature is more than 25¡æ or the mixing quantity is too large,the curing speed after two components mixing will expedite,should properly shorten the application

time of coating after mixing.

Construction protective measures:

1.Wear the protective masks,wear the protective glasses and rubber gloves

2.Need washing hands with soap before eating,drinking or smoking.

3.The health hazard after touching: a few people will have skin allergy phenomenon,see a doctor in time and avoid touching with this product again.should wipe it with ethyl acetate when the sizing material paste on the skin by

careless,then wash it with clear water.Should wash it with clear water immediately and see a doctor when splashing into the eyes by careless.

Safety/Health:

This product is a general chemical. Excessive exposure may cause allergic skin diseases. Air circulation should be kept smooth in the construction environment.Wear general work clothes, dustproof mask, protective glasses and

gloves during construction to avoid contact with eyes and skin. In case of accidental contact, rinse with running water repeatedly as soon as possible. If necessary, please seek medical advice immediately.

Transportation storage

Sealed storage in the cool and dry place.The warranty period is 12 months.Keep away from dangerous sources during storage and transportation.Avoid placing it upside down, knocking against and transporting it as a non-dangerous

product during transportation.

Packaging specification

2 components,10kg/set or 20kg/set,plastic drums + carton packaging.

resistant coating

compound

resistant coating

repair coating

epoxy adhesive

coating

insulation coating

coating

coating

adhesive

resistant adhesive

structural adhesive

agent

bonding adhesive

adhesive

anti seizure compound

resistant agent

fastening adhesive